Guide to vertical mill roller selection in the mining cement industry

In the mining cement industry, the vertical mill is the core equipment for grinding raw materials, coal, cement clinker and slag, and the vertical mill roller is its key vulnerable part. Choosing the right roller is crucial to ensure stable operation of the equipment, improve grinding efficiency, reduce unit energy consumption and control maintenance costs. Many factors need to be considered when selecting:

Core selection factors

1. Material characteristics (this is the primary factor):

Abrasiveness: The content of hard minerals such as quartz, flint, and alumina in the material. The higher the content, the stronger the abrasiveness, and a higher hardness and more wear-resistant material (such as high-chromium cast iron, composite wear-resistant materials) is required.

Grindability: The difficulty of grinding the material. Materials with poor grindability require the roller to withstand greater pressure and friction.

Particle size: The size and distribution of the feed particle size. Large particle size and wide distribution, large impact force, require the roller to have good impact toughness.

Moisture: High moisture content may cause adhesion and paste grinding, affecting grinding efficiency and increasing additional load.

Chemical composition: Certain chemical components (such as alkali and chloride ions) may corrode certain materials.

2. Working conditions:

Grinding pressure/rolling pressure: The greater the pressure, the higher the load on the roller, requiring the material to have higher strength and fatigue resistance.

Line speed: Affects wear rate and impact force.

Output: High output means higher material throughput and wear.

Equipment model and specifications: Different models of vertical mills (such as Loesche, Atox, MPS, RM, TRM, etc.) have different roller structures, sizes, and working methods (such as roller sleeve type, integral type, tire type), which directly affect the selection of rollers.

Grinding disc lining matching: The grinding roller material usually needs to match the grinding disc lining material to achieve the best wear resistance and grinding efficiency. The hardness and wear resistance of the two need to be coordinated.

3. Grinding roller material (this is the core of the technology): Main material types and characteristics:

High Chrome Iron (High Chrome Iron - HCI):

Advantages: High hardness (up to HRC 60-67), excellent wear resistance, it is the most widely used grinding roller material in the cement industry. Suitable for highly abrasive materials (such as raw materials, slag, clinker).

Disadvantages: Relatively low toughness, slightly poor impact resistance. It is easy to crack and peel under the impact of large pieces of materials or foreign objects. The casting process has high requirements and quality control is difficult.

Applicable: Grinding of materials with strong abrasiveness and little impact (mainstream choice).

Nickel Hard Cast Iron (Ni-Hard):

Advantages: High hardness (HRC 55-63), good wear resistance, and the cost is usually lower than high chromium cast iron.

Disadvantages: The toughness is worse than high chromium cast iron, it is more brittle, and the impact resistance is the weakest. It is more likely to crack under high impact or sudden temperature change.

Applicable: Specific working conditions with strong abrasiveness and very small impact (application is gradually decreasing).

Forged Steel:

Advantages: Good toughness, excellent impact resistance, not easy to crack. The surface hardness can be improved by surface hardening treatment (such as surfacing wear-resistant layer).

Disadvantages: The overall hardness is usually lower than that of high-chromium cast iron (low matrix hardness), and the wear resistance of the body is relatively poor. Relying on the surface hardening layer, the number of repairs is limited.

Applicable: Working conditions with large impact, large material particle size, and relatively medium abrasiveness (such as some coal mills).

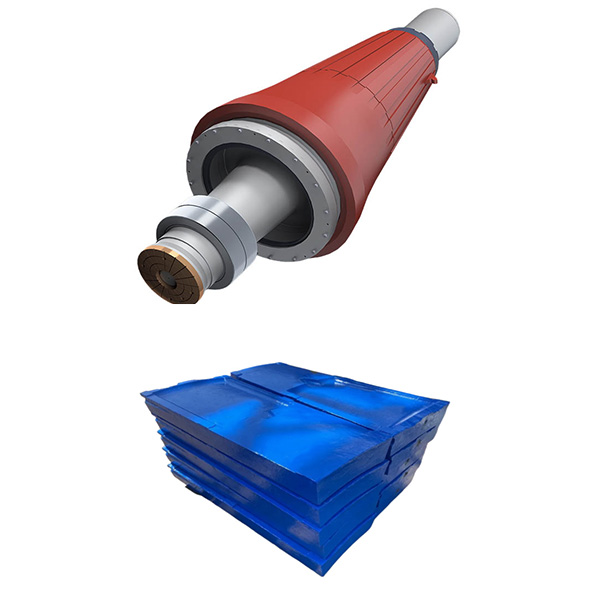

Composite Roll Tyres: This is the current development trend of large vertical mills.

Structure: Usually composed of forged steel or ductile iron roller core with good toughness + high hardness and high wear resistance of alloy cast iron (usually high chromium cast iron) roller sleeve.

Advantages:

Impact resistance: The tough roller core absorbs impact and protects the brittle wear-resistant layer.

Wear resistance: The roller sleeve is made of the best wear-resistant material.

Replaceable: After wear, only the roller sleeve needs to be replaced, saving costs (especially for large grinding rollers).

Repairable: Some designs allow for surfacing repair of the roller sleeve surface to extend life.

Disadvantages: Complex structure, high manufacturing cost, and high assembly precision requirements.

Applicable: The mainstream choice for large raw mills, slag mills, and clinker mills.

Surface surfacing (Hardfacing):

Application: Mainly used in the manufacture of wear-resistant layers of alloy forged steel or composite roller sleeves, and repair of grinding rollers after wear.

Advantages: The chemical composition, hardness and wear resistance of the surfacing layer can be flexibly designed (such as the hardness of the tungsten carbide particle reinforced surfacing layer can reach HRC 65+), and the wear resistance is excellent. Repair can extend the life of the grinding roller body.

Disadvantages: The surfacing process is complex, the cost is high, and there is a risk of thermal cracking. The number of repairs is limited by the thickness of the substrate. Peeling of the wear-resistant layer is the main failure form.

Applicable: As the wear-resistant working surface of forged steel grinding rollers; used for the manufacture and repair of composite roller sleeves; special working conditions with extremely high wear resistance requirements.

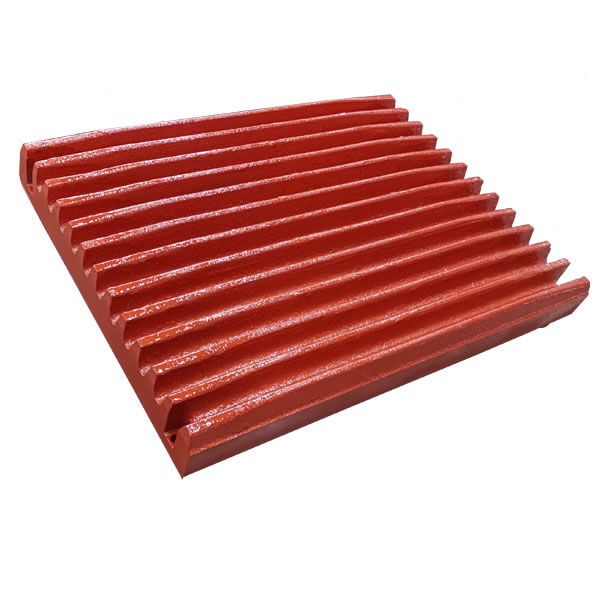

The grinding rollers produced by our company

Current trend

Composite roller sleeves have become the mainstream of large vertical mill rollers: due to their excellent comprehensive performance (wear resistance + impact resistance) and the economy brought by replaceable roller sleeves.

Continuous optimization of high chromium cast iron material: by improving the composition design (such as adding molybdenum, copper, nickel, etc.), heat treatment process and casting technology (such as centrifugal casting), its toughness and wear resistance are improved, and the risk of cracking and peeling is reduced.

Wide application of surfacing technology: used for new roller manufacturing (especially forged steel matrix) and old roller repair, providing extremely high surface wear resistance. Tungsten carbide composite surfacing layer performs outstandingly under extreme abrasive conditions.

Intelligent and predictive maintenance: Use sensors to monitor parameters such as roller vibration and temperature, combined with wear models, to achieve roller status monitoring and life prediction, optimize replacement plans, and reduce unplanned downtime.

Summary

There is no best answer for selecting mining cement vertical mill rollers. The key is to deeply understand your specific material characteristics, equipment conditions and operating goals, and work closely with strong and experienced suppliers. Give priority to composite roller sleeves or high-quality high-chromium cast iron materials, and attach great importance to the supplier's manufacturing quality, technical support and life cycle costs. Through scientific selection and good maintenance, you can maximize the service life and economic benefits of the grinding roller and ensure the efficient and stable operation of the vertical mill. Before making a final decision, be sure to ask the supplier to provide a detailed technical solution and expected life commitment for your specific conditions.