High-Chromium Heat-Resistant Cast Iron Material Replacement and Sand Casting Process Optimization Case Study

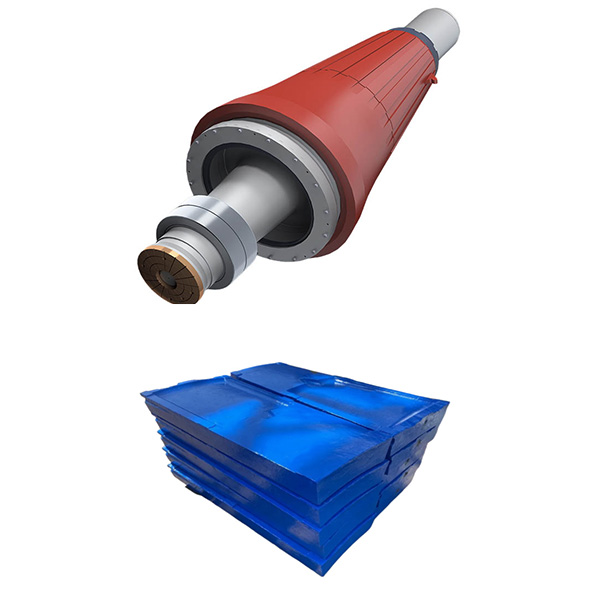

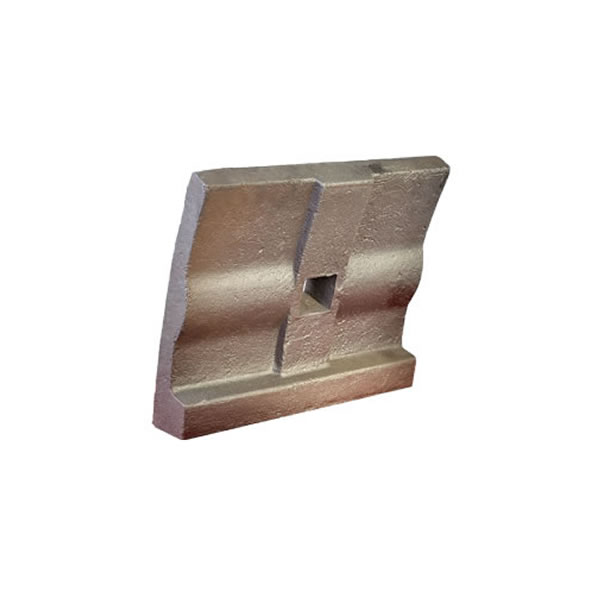

A large cement company's 3000 t/d production line grate cooler's medium- and low-temperature zone grate plates, originally made of ZG2Cr20Mn9Ni2Si2N material, suffered from short service life (average 4 months) and high replacement costs. To address this problem, the company collaborated with a foundry to upgrade the technology, replacing the traditional heat-resistant steel with HTRCr16 high-chromium heat-resistant cast iron and optimizing the sand casting process.

Key Technical Improvements:

1. Material Optimization: HTRCr16 high-chromium heat-resistant cast iron was selected, with a chromium content controlled at 15%-18%, forming a dense Cr₂O₃ oxide film. It can withstand long-term operating temperatures up to 900℃, suitable for medium- and low-temperature conditions, and the material cost is 30% lower than the original material.

2. Melting Process Control: Medium-frequency furnace melting was used, with strict temperature control during the addition of ferrochrome to avoid oxidation losses. Argon gas stirring and refining were employed to remove inclusions and ensure the purity of the molten iron.

3. Casting and Heat Treatment Optimization: Pouring temperature was controlled at 1480-1500℃, and risers and chills were rationally designed to reduce shrinkage defects; a heat treatment process of 930℃ normalizing + 600℃ tempering was adopted to refine carbides and eliminate casting stress, improving material toughness.

4. Enhanced Quality Inspection: High-temperature oxidation tests were added to verify durability, ensuring that the oxidation rate in an 800℃ oxidizing atmosphere is less than 0.1 mm/year.

Application Results: The improved grate plates have a service life of 8 months, a 100% increase compared to the original material; each production line can save approximately 280,000 RMB in grate plate replacement costs annually, and the material has better processing performance, with the casting scrap rate reduced from 5.2% to 2.1%.