Replacement Guide for Wearing Parts of Cement Plant Roller Press

As the core equipment of the grinding system, the cement plant roller press has an extremely harsh working environment (high dust, high pressure, high impact, high wear). Therefore, many parts are wearing parts and need to be replaced regularly or according to wear conditions. The following are the parts that need to be replaced most often and their reasons:

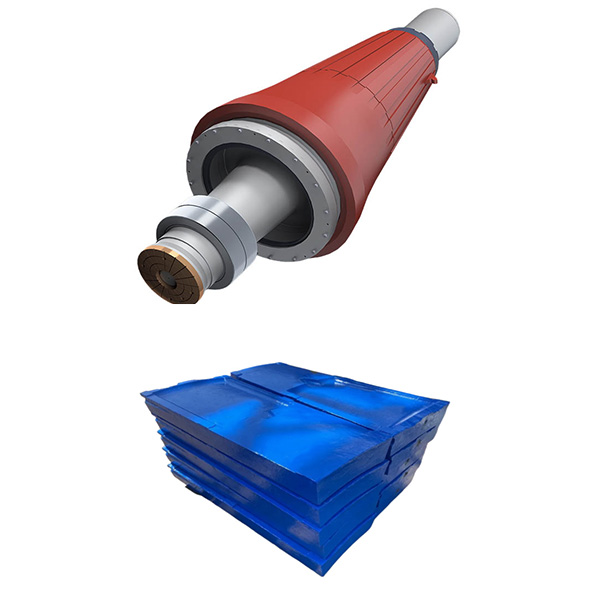

Roller surface parts (direct contact with materials, the most severe wear):

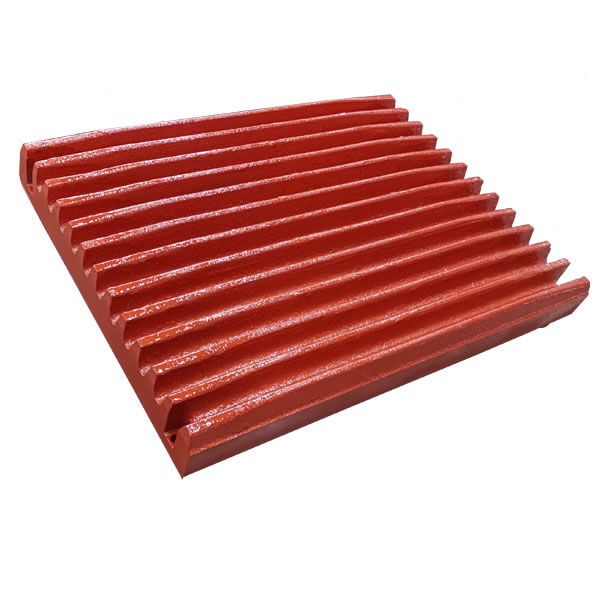

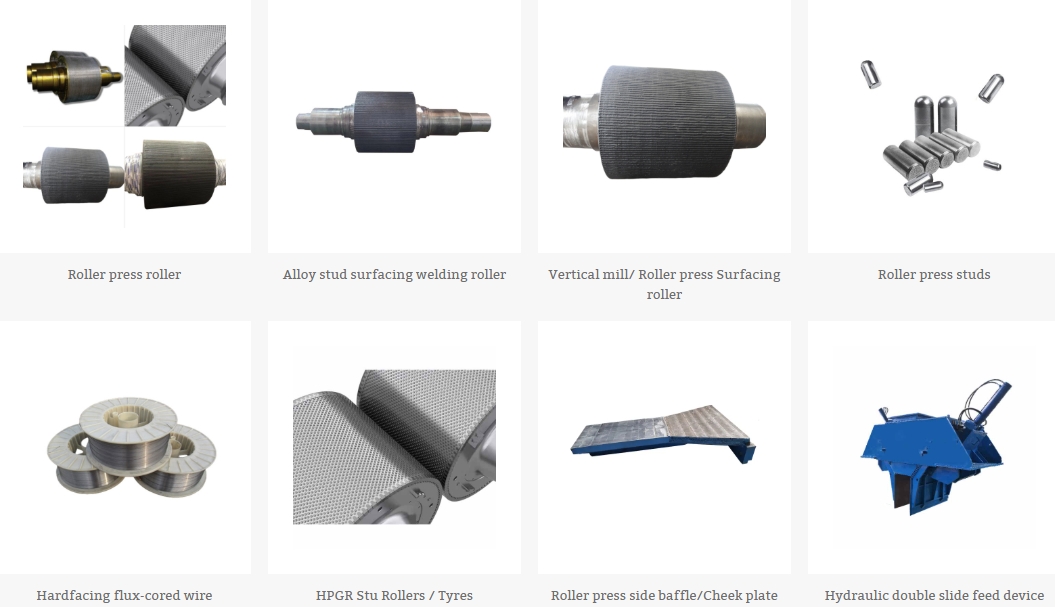

Roller nails/roller teeth: This is one of the fastest wearing parts. They are directly embedded in the roller skin or as part of the wear-resistant layer, and bear the direct impact, extrusion and shear wear of the material. When the wear reaches a certain level (such as height reduction, shape change, and shedding), it will seriously affect the extrusion effect and output, and must be replaced.

Roller skin/wear-resistant lining: The outer wear-resistant surface of the roller. Although it is more wear-resistant than roller nails, it will gradually wear, fatigue, and even peel off under long-term high-stress extrusion and material friction. Uneven wear will cause changes in the roller gap and increased vibration, which requires surfacing repair or overall replacement. The replacement cycle is longer than roller nails, but it is still a key wearing part.

Hydraulic system components (maintaining the operating pressure of the roller press):

Hydraulic cylinder seals: including piston seals, rod seals, static seals, etc. Working for a long time in a high pressure, high temperature, and dusty environment, it is easy to age, wear, and deform, resulting in hydraulic oil leakage and unstable pressure, and must be checked and replaced regularly.

Accumulator bladder: Absorb shock and stabilize system pressure. The bladder will rupture and fail due to fatigue and aging. It is necessary to regularly detect the nitrogen pressure and bladder status and replace them in time.

Hydraulic oil filter element: Filter impurities and wear metal particles in the hydraulic oil to protect precision hydraulic components. It must be replaced strictly according to the maintenance cycle, otherwise it will accelerate the wear of pumps, valves and other components.

Bearings (support rollers and bear huge loads):

Roller bearings: Bear huge radial forces and certain axial forces, and the working environment is high temperature and there is a risk of dust intrusion. Although the design life is long, it will be damaged in advance (fatigue peeling, cage damage, jamming, etc.) under impact loads, poor lubrication, seal failure or improper installation, and needs to be replaced. It is a key spare part with high value.

Reducer bearings: They also bear heavy loads and impacts, and require good lubrication and sealing. The reasons for damage are similar to roller bearings.

Lubrication system components (to ensure the normal operation of key components such as bearings):

Lubricating grease: They need to be replenished and replaced regularly, especially for open gears and other parts.

Lubrication pipelines and joints: They may be damaged or leak due to aging, vibration, external force, etc.

Lubrication pump/distributor: Key components that require maintenance and need to be replaced when damaged.

Feed device components (guiding materials and bearing scouring):

Feed baffle/adjustment plate: Guides materials into the roller gap and directly bears the scouring and wear of high-speed materials, especially the edges and guide surfaces, which wear faster.

Side baffles: Installed at both ends of the roller to prevent materials from leaking from the side. The gap with the roller end face is very small, and it is subject to material extrusion and friction wear, and is also easily damaged. The gap needs to be adjusted or replaced regularly.

Roller press parts produced by our company

Scraper device (cleaning adhered materials):

Scraper blade: Close to the roller surface, scrape off the materials adhering to the roller. It is a wear-resistant part, but it will wear out and become shorter or damaged and fail under continuous friction with the roller surface, and needs to be replaced. Failure will cause materials to accumulate on the roller surface, affecting operation.

Transmission system components:

Universal coupling cross shaft and bearings: Transmit torque and compensate for installation errors. The cross shaft and bearings work under heavy loads, impacts and certain angles, and are vulnerable points.

Reducer gear oil: Need to be replaced regularly to maintain cleanliness and performance.

Motor bearings: Need maintenance and replace when damaged.

Seals (dust and leakage prevention):

Bearing seals: Prevent dust from entering the bearing cavity and lubricating oil leakage, which is the key to bearing life. Lip seals and labyrinth seals The contact parts or sealing strips will wear and age and need to be replaced.

Other static seals: O-rings, gaskets, etc. of various joint surfaces, flange surfaces, pipe joints, etc. of the equipment need to be replaced after aging to prevent leakage.

Key factors affecting replacement frequency:

Material properties: Hardness, particle size, moisture, abrasiveness (such as quartz content) are decisive factors. The harder and more abrasive the material, the faster it wears.

Equipment operating parameters: working pressure, roll gap, processing capacity, operating hours. The higher the pressure and the larger the processing capacity, the faster the wear.

Operation and maintenance: whether the feeding is stable and uniform, whether there is any metal foreign matter entering, whether the lubrication is in place in time, whether the inspection is careful, the quality of installation, etc.

Quality of the parts themselves: the grade of wear-resistant materials, manufacturing process, and heat treatment level.

System process: whether combined grinding, semi-final grinding, etc. are used, and different cyclic loads also affect the wear of the roller press.

Summary:

The core of roller press maintenance is to manage wear and hydraulic/lubrication. Roller nails, roller surfaces, hydraulic seals, bearings, scrapers, side baffles, and feed device wear parts are the parts with the highest replacement frequency. Establishing a sound inspection system, oil monitoring system, and accurate spare parts inventory management is essential to ensure the stable operation of the roller press and reduce the overall maintenance cost. The specific replacement cycle needs to be determined based on actual working conditions and maintenance experience.

Recommended spare parts inventory priority (based on replacement frequency and criticality):

High priority (frequent replacement): roller nails, scraper blades, hydraulic seal kits, hydraulic filter elements, lubricating oil filter elements, side baffle wear strips/plates, feed baffle wear parts.

Medium priority (periodic replacement or accidental damage): roller skin/wear-resistant lining (or surfacing materials), bearings (roller bearings, reducer bearings), accumulator bladders, universal coupling cross shafts and bearings, various sealing strips/O-rings.

Low priority (long life or low damage rate): large structural parts, hydraulic cylinders, reducer housings, motors, etc. (usually replaced only when planned overhauls or accidental serious damage occur). However, key large bearings and roller skins should have a certain strategic reserve because the procurement cycle is long.