To further optimize cement production processes and improve equipment operating efficiency and stability, the CEO of a large Indian cement plant recently led a delegation comprised of key department heads from production, equipment, and procurement to our company's equipment manufacturing plant in Yunnan Province for an on-site visit and in-depth discussions. The visit aimed to "precisely address needs, verify production capabilities, and jointly explore cooperation paths," laying a solid foundation for future collaboration.

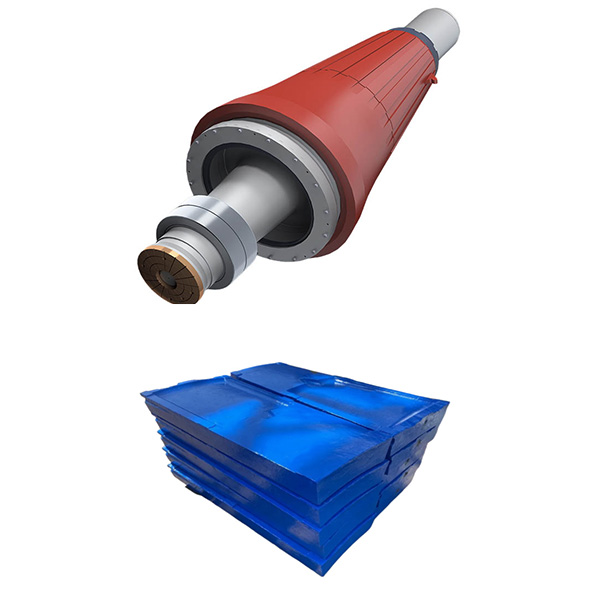

Upon arriving at the Yunnan factory, the delegation, accompanied by General Manager Guo, first entered the production workshop. They were greeted by a clean and orderly production scene: robotic arms precisely welding parts, CNC lathes operating at high speed to process core components, and factory workers diligently performing their duties. "Our equipment manufacturing strictly adheres to the ISO9001 quality system standard," General Manager Guo explained as he guided the delegation on a tour. The delegation members lingered at the production stations for core equipment components such as cement mills, rotary kilns, and crushers, carefully observing the structural design, processing technology, and assembly details, and frequently exchanging questions with the factory's technical staff. Picking up a sample of a wear-resistant liner, the delegation examined its material density and surface treatment, remarking, "The cement production environment is harsh; the wear resistance and high-temperature resistance of equipment directly affect production efficiency. Your process details are indeed very professional, and the tea quality is excellent."

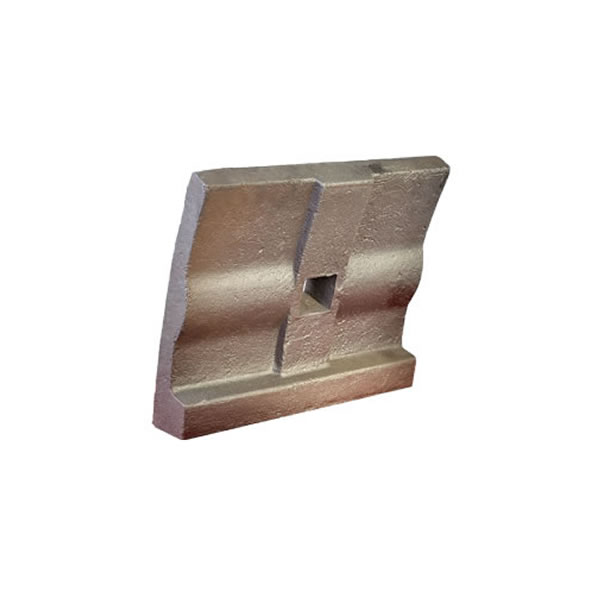

After the factory tour, they were invited to our company headquarters in Luoyang for a discussion on their concerns. During the meeting, both sides engaged in in-depth exchanges on topics such as industry development trends, equipment technology upgrades, and innovative cooperation models. The Indian client expressed interest in collaborating on cast nail rollers for roller presses and ceramic grinding rollers for vertical mills. They had previously used rollers manufactured in India, but these had a very short lifespan, requiring frequent downtime for repairs, which significantly disrupted production. After visiting our factory, they decided to purchase from us. They will send us the relevant drawings soon. We also recommended our wear-resistant hammers and blow bars for crushers. These products utilize the latest R&D technology and have a service life more than twice that of our competitors. They expressed great interest and will check their spare parts inventory and usage after returning home, so we can develop a cooperation plan tailored to their production environment.

This visit by the cement plant customer not only built a bridge for efficient communication between our two parties but also allowed them to directly experience our equipment factory's strength and sincere service. In the future, both parties will use technological cooperation as a link and win-win development as a goal to continuously promote the implementation of cooperation and inject new momentum into the high-quality development of the cement industry.