SAG Mill Wear-Resistant Parts: A Key Cornerstone for Improving Grinding Efficiency and Equipment Life

At the heart of the mining process, the semi-autogenous (SAG) mill, with its unique crushing power, undertakes the crucial task of processing hard ores. However, the harsh grinding environment subjects the mill to constant, intense impact and wear. High-quality wear-resistant parts are crucial for ensuring efficient, stable, and long-term operation of the SAG mill. They are not only the equipment's "protective armor" but also a decisive factor in improving overall production efficiency.

Analysis of Core Wear-Resistant Parts

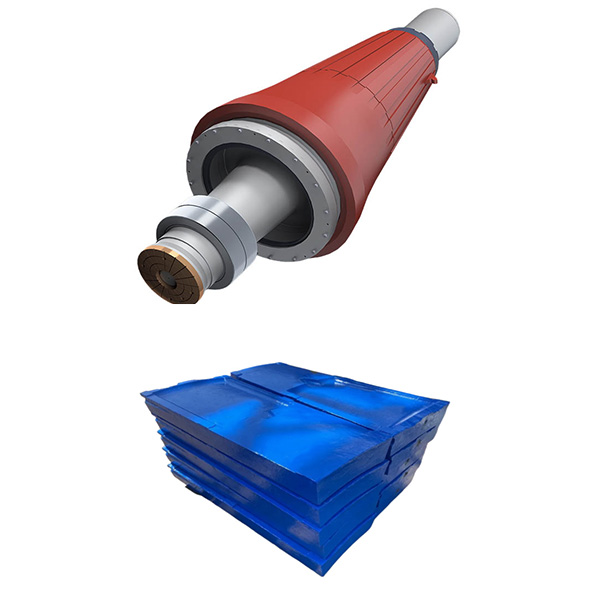

1. Cylinder Liner: The "inner armor" of the cylinder.

Function: Directly withstands the impact, sliding, and rolling wear of the grinding media (steel balls, ore itself) and the material, protecting the cylinder from wear.

Key Point: Lifting bar design is crucial, directly affecting the material's trajectory within the mill and energy efficiency. Typically constructed of high-chromium cast iron, the impact zone requires increased toughness.

2. End Liners (Feed/Discharge): Critical barriers protecting both ends of the mill. Feed Liner: Withstands the intense impact of fresh ore and is subject to severe wear. It requires extremely high impact and wear resistance, and is often made of tough alloy steel or high-chromium cast iron.

Discharge Liner/Grate: Controls discharge particle size and material flow rate. The grate's design (aperture, porosity, and structure) directly impacts the mill's production capacity and product particle size distribution, requiring extremely high wear resistance.

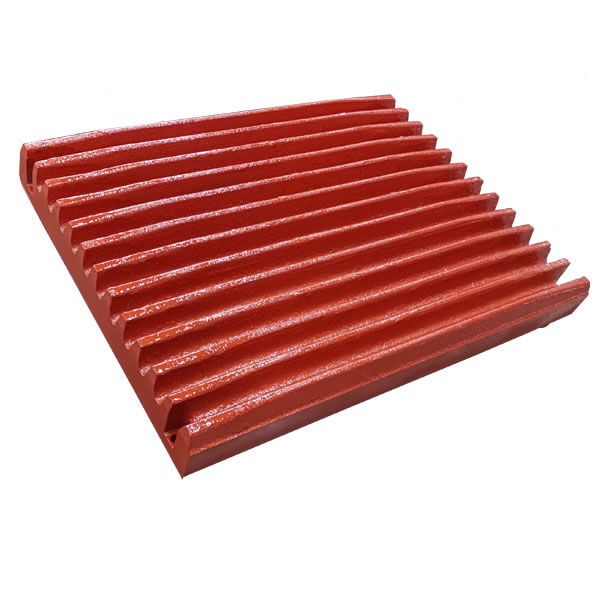

3. Lifting Bar: The "energy engine" within the mill.

Function: Lifts the grinding media and material as the drum rotates, causing them to reach a certain height before being thrown down, creating an impact crushing effect. It is a key factor influencing mill power consumption and grinding efficiency.

Key Points: The shape, height, material, and mounting method directly determine the lifting effect and lifespan of the mill. Wear requires prompt replacement to maintain mill efficiency.

4. Grate: The "screen" that precisely controls ore discharge.

Function: Installed at the discharge end, it blocks grinding media and unqualified coarse particles, allowing the discharge of slurry of acceptable particle size.

Key Points: Extremely high wear resistance is required to resist slurry erosion, precise aperture design ensures controlled discharge particle size, and a sturdy structural design prevents deformation and breakage. High-chromium cast iron is the mainstream material.

5. Fasteners (bolts, nuts, washers): Indispensable "safety locks."

Function: Ensures that all liners, lifting bars, and gratings are securely fastened to the cylinder and end caps to prevent them from falling and causing serious accidents.

Key Points: Must be manufactured from high-strength, high-toughness alloy steel with excellent shear, tensile, and fatigue resistance, and equipped with reliable anti-loosening features (such as self-locking nuts and special washers). Regular inspection of tightening status is a key maintenance priority.

Key Advantages of Choosing a Professional Manufacturer

Deep Technical Experience: A deep understanding of the operating principles, wear mechanisms, and abrasive properties of SAG mills, enabling the provision of tailored solutions.

Material R&D and Customization Capabilities: We have material laboratories and formulation development capabilities, enabling us to tailor optimized material solutions based on our customers' specific operating conditions (e.g., ore hardness, mill specifications, and operating parameters).

Advanced Manufacturing and Quality Control Systems: We utilize modern casting, heat treatment, and machining equipment, and adhere to strict quality control standards (e.g., ISO) to ensure the stable and reliable performance of every product.

Comprehensive Technical Support: We provide professional installation guidance, wear monitoring recommendations, failure analysis, and spare parts inventory optimization solutions, providing a solid foundation for our customers' stable operations.

A sophisticated global supply chain and delivery guarantee: We ensure a timely and stable supply of large-scale wear-resistant parts, minimizing customer downtime.

Zhili New Materials: Your Trusted Partner for Wear-Resistant Solutions for SAG Mills

As experts in wear-resistant materials and parts for many years, Zhili New Materials deeply understands the critical importance of stable SAG mill operation to the overall profitability of a mine. We specialize in:

Providing customized, high-performance, long-life wear-resistant parts: We strive for excellence throughout the entire process, from material selection and structural design to precision manufacturing.

Maximize your mill's uptime: Reduce unplanned downtime and improve equipment utilization.

Significantly reduce wear costs per ton of ore: Excellent wear resistance translates directly into significant economic benefits.

Optimize grinding efficiency and product quality: Scientific design helps increase throughput and achieve target particle size control.