Double-toothed Roller Crusher Main Wear Parts

A double-toothed roller crusher is a more specialized roller crusher. Its core feature lies in the specially designed toothed roller skins mounted on its two rollers. These rollers crush materials through a variety of forces, including shearing, stretching, and splitting. They are particularly suitable for medium and coarse crushing of low- to medium-hardness materials.

I. Core and Featured Wear Parts

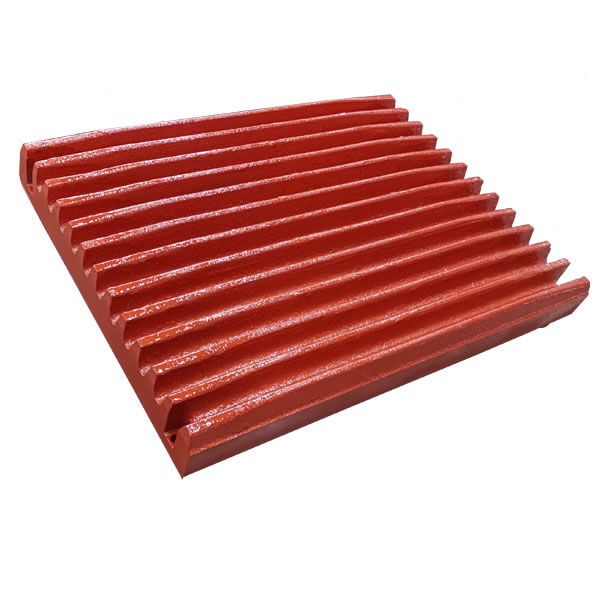

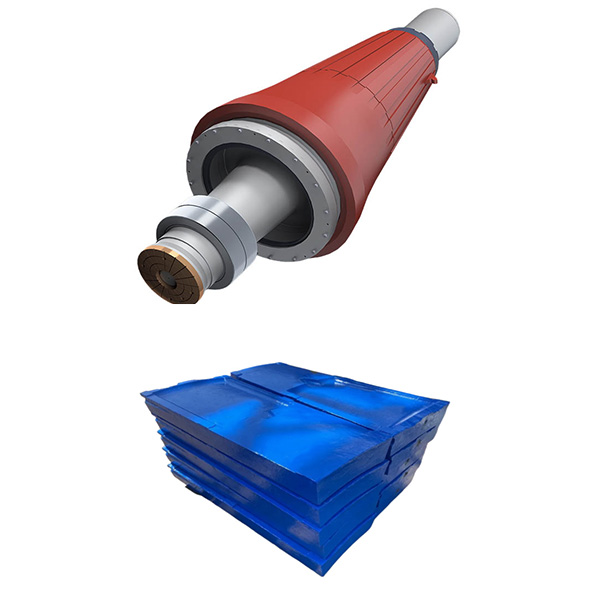

1. Toothed Roller / Crushing Teeth

What is it? This is the core and most distinctive wear part of the double-toothed roller crusher. It is no longer a smooth or patterned roller skin. Instead, it consists of a tooth adapter and a tooth cap (also called a lance head or tooth tip), or a single, integral alloy casting.

Why are they so vulnerable? These protruding teeth directly penetrate, pull, and shred the material, with the tooth tips bearing the most severe wear and impact. They wear extremely quickly, far exceeding the roller skins of ordinary roller crushers.

Material and Type:

Integral Crushing Teeth: Made from a single, wear-resistant alloy, such as high-manganese steel or high-chromium cast iron, they offer a simple structure and high strength.

Split-type crushing teeth (tooth adapter + tooth cap): This is the most common design. The tooth adapter is welded or bolted to the roller core and is made of a tough material. The tooth cap is fixed to the tooth adapter via bolts or pins. It is a purely wear-resistant component. When worn, only the tooth cap needs to be replaced, significantly reducing maintenance costs and replacement time.

Failure Modes: The tooth cap wears out, becomes blunt, breaks, or loses pieces. The tooth adapter may also deform or crack in extreme cases.

2. Bearing and Sealing System

Importance: As with conventional roller crushers, bearings are critical components that support the two toothed rollers and withstand significant radial and impact forces. Due to the extremely dusty operating environment, the effectiveness of the seal directly determines the bearing life.

Why They Are More Fragile: The vibration and impact generated by the double toothed rollers during crushing can be more severe, placing greater strain on the bearings. Once the seal fails, sharp dust particles quickly contaminate the grease and abrade the bearings, leading to rapid failure.

Failure Modes: Bearing retainer fracture, raceway pitting, spalling, and seizure. Seal lip wear and aging. Summary and Maintenance Recommendations

The core maintenance of the twin-roll crusher's wearing parts lies in the "rollers" and "bearings."

Regular Inspection and Rotation: Regularly inspect wear. For integral rolls, rotate the entire roll when wear reaches a certain level to extend its life.

Material Matching: Select the most economical roll cap material (such as high-manganese steel or high-chromium cast iron) based on the material's characteristics (abrasiveness and hardness).

Strictly Protect Bearings:

Ultimate Lubrication: Strictly lubricate according to the specified cycle and grade, and regularly check the grease condition.

Seal Effectiveness: Check the seal condition during every maintenance and replace any failed seals promptly. This is the most economical and effective way to protect the bearings.

Installation and Operation Are Key:

Uniform Feeding: Use a feeder to ensure that the material is evenly distributed across the entire roll length to prevent localized wear of the rolls.

Strong Iron Removal: Install an iron remover above the feed conveyor to prevent the ingress of non-crushable objects such as iron. This is the most effective preventative measure to prevent broken teeth and equipment damage.

Regular Tightening: During routine inspections when the equipment is down, check and tighten all bolts, especially those securing components such as the tooth adapter, tooth cap, and liner.

In summary, the primary wear component of a double-roll crusher is the tooth roller, followed by the bearings and comb plates. Choosing the right tooth roller and ensuring proper bearing seal maintenance are key to controlling operating costs.