Cement Plant Crusher Hammers Set a New Benchmark in Wear Resistance – High Manganese Steel Embedded with Titanium Carbide Alloy Rods + Surface Hardfacing

In the vast cement production system, hammer crushers are key players in crushing raw materials such as limestone and clinker. The performance of their core component, the crusher hammer, directly determines production efficiency, operating costs, and equipment reliability. Faced with the severe abrasive loads and unpredictable impact loads of high-silicon limestone, traditional hammers made of a single material often face a dilemma: wear resistance without toughness, and toughness without wear resistance. Now, a design that integrates cutting-edge composite materials and advanced surface engineering – a high manganese steel matrix embedded with titanium carbide (TiC) alloy rods + surface hardfacing – is emerging as the ultimate solution for high-end cement crushing applications with its superior overall performance.

I. Limitations of Traditional Hammer Materials

While materials such as high manganese steel and high-chromium cast iron each have their own applications, they all exhibit inherent shortcomings under extreme operating conditions:

High manganese steel: Relying on intense impact to harden, it suffers from insufficient hardening in actual operating conditions, resulting in suboptimal wear resistance and susceptibility to plastic deformation. High-chromium cast iron: It possesses extremely high hardness and wear resistance, but is also highly brittle. When impacted by foreign objects or large pieces of material, it is prone to fracture and chipping, even causing serious equipment safety accidents.

Conventional bimetallic composite hammer heads: While they combine wear resistance and toughness, the interface between the wear-resistant layer (e.g., high-chromium cast iron) and the tough layer remains a weak point. Under sustained high-stress impact, delamination can occur.

II. Disruptive Innovation: High-manganese steel embedded with titanium carbide alloy rods + Surface Hardfacing Technology

This solution is not a simple material replacement; it involves a systematic, multi-layered "armor upgrade."

1. Tough Foundation: High-manganese Steel Matrix

The hammer head utilizes optimized high-manganese steel as its base. Its core value lies in its unparalleled toughness and impact fatigue resistance. Under significant impact loads, the high-manganese steel matrix absorbs energy through plastic deformation, ensuring the hammer head will not fracture, providing a fundamental safety guarantee for the entire design.

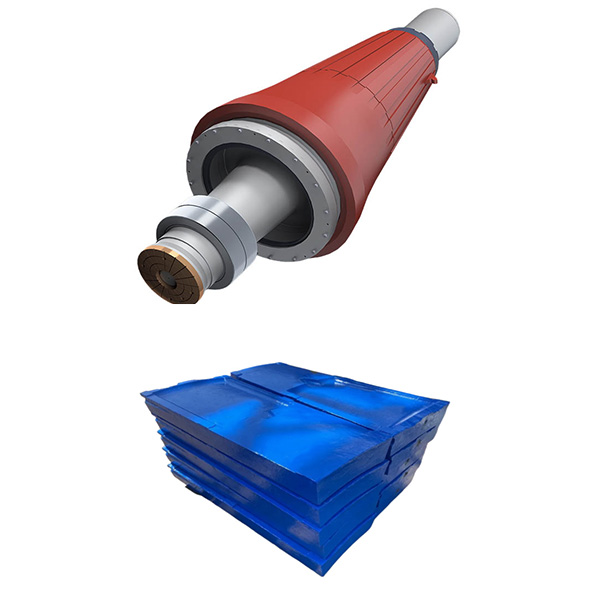

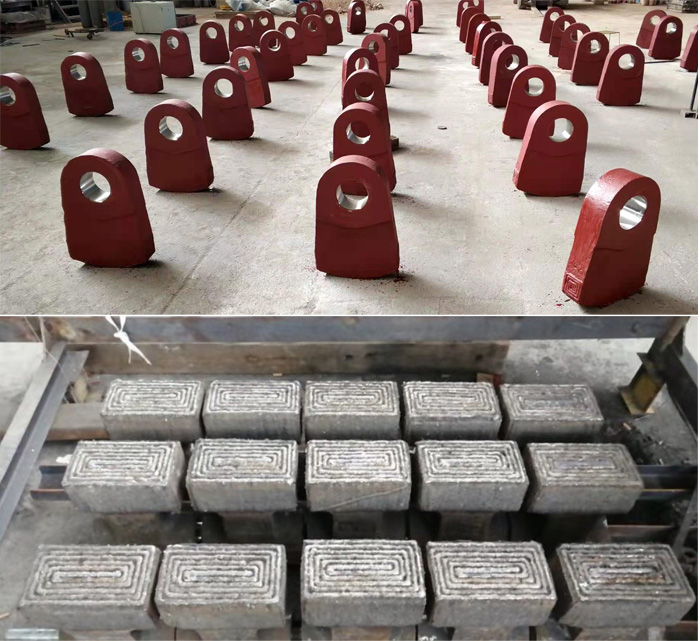

2. Internal "Diamond Keel": Titanium Carbide (TiC) Alloy Rod Inlay

Pre-drilled holes are placed in core areas of the crusher hammer head prone to wear (such as the hammer tip) to embed extremely hard titanium carbide (TiC) alloy rods. With a microhardness exceeding HV3000, TiC is one of the hardest materials in the world, and its wear resistance far exceeds that of high-chromium cast iron.

Purpose: These alloy rods, like rebar in concrete, form the hammer head's internal "wear-resistant skeleton." They directly absorb the primary abrasive wear, significantly slowing the wear process.

Advantage: Unlike cast composites, mechanical inlay avoids oxidation and porosity at the bonding interface, resulting in a more reliable bond. Even after the surface wear material is depleted, the internal TiC rods continue to provide protection.

Display of inset alloy bars hammer heads produced by our company

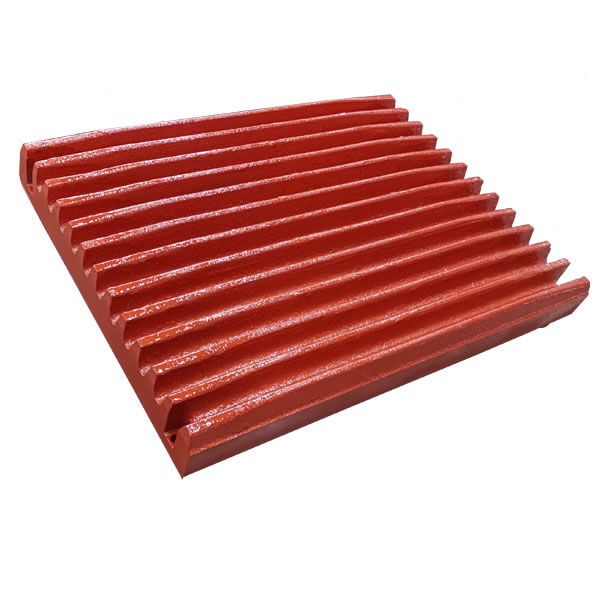

3. Surface "Armor-Piercing Blade": Specialized Wear-Resistant Hardfacing

Automated equipment is used to deposit a special wear-resistant weld bead on the hammer head's working surface (especially the impact surface). This weld bead is designed specifically for cement abrasives, which are typically rich in hard phases such as high-carbon, high-chromium alloys and tungsten carbide (WC) particles.

Purpose: Serving as the first line of defense, the surface weld layer directly contacts the material, providing exceptional hardness against abrasive wear. Its uneven weld bead also effectively reduces material slippage, improving crushing efficiency.

Advantages: The weld bead can be tailored to the specific material characteristics, offering exceptional flexibility. Wear can even be repaired on-site, significantly extending the hammer's overall lifespan and significantly reducing the frequency and cost of purchasing new hammers.

The hardfacing hammer head produced by our company

III. Why This Solution? Four Core Advantages

Ultimate Safety: The high-manganese steel base fundamentally eliminates the risk of breakage, addressing the primary safety concern of high-chromium cast iron hammers. It is particularly suitable for handling unforeseen large pieces of material or foreign objects.

Unparalleled Wear Life: The "TiC alloy rod (internal) + weld overlay (surface)" system provides a dual wear-resistant system, typically lasting 2-3 times or even longer than high-quality high-chromium cast iron hammers, significantly reducing downtime and replacement time.

Excellent Overall Cost-Effectiveness: While the initial purchase cost is higher, the exceptionally long lifespan not only saves on the hammer itself, but also delivers a comprehensive return in reduced downtime, lower labor costs for replacement, and increased production efficiency. The cost per ton of material crushed is significantly reduced.

Repairability and Sustainability: When the weld overlay wears out, it can be quickly repaired during regular maintenance, allowing the hammer base to be reused, aligning with the green manufacturing philosophy of energy conservation, consumption reduction, and emission reduction.

IV. Applicable Operating Conditions

This solution is the "flagship choice" for the most demanding operating conditions and is particularly recommended for:

Crushing extremely abrasive limestone with a high silicon content (SiO₂ > 8%).

Complex operating conditions with large variations in material particle size and the coexistence of impact and wear.

Large-scale modern cement production lines pursue ultra-long operating cycles and minimize spare parts replacement.

Equipment downtime is costly, and production continuity is crucial.

Conclusion

With increasingly fierce competition in the cement industry, where cost reduction and efficiency improvement are paramount, forward-looking investment in key spare parts (crusher hammers) is a wise move. The hammer head, comprised of high-manganese steel inlaid with titanium carbide alloy rods and welded on the surface, represents the current state of the art in crusher hammer technology with its innovative design and exceptional operational performance. It's not only an alternative to traditional solutions but also a strategic choice for cement companies to enhance their core competitiveness and achieve sustainable development. Investing in a more wear-resistant and safer hammer head is an investment in a more productive, stable, and profitable future.