A Detailed Explanation of Spare Parts for Grinding and Crushing Equipment in Metal Mines

Metal mines use a wide variety of grinding and crushing equipment, and their accessories also constitute a vast and specialized system. These accessories are generally categorized by the equipment's operating mode (e.g., extrusion, impact, grinding) and the different parts of the equipment in which they are installed.

The following is a detailed introduction to the main grinding and crushing equipment used in metal mines and their core accessories:

I. Crushing Equipment and Accessories

Crushing equipment is primarily responsible for coarse and secondary crushing of ore, reducing large ore chunks to a particle size suitable for feeding into the grinding mill.

1. Jaw Crusher

Working Principle: Ore is crushed through the periodic squeezing motion between the movable and fixed jaws.

Core Accessories:

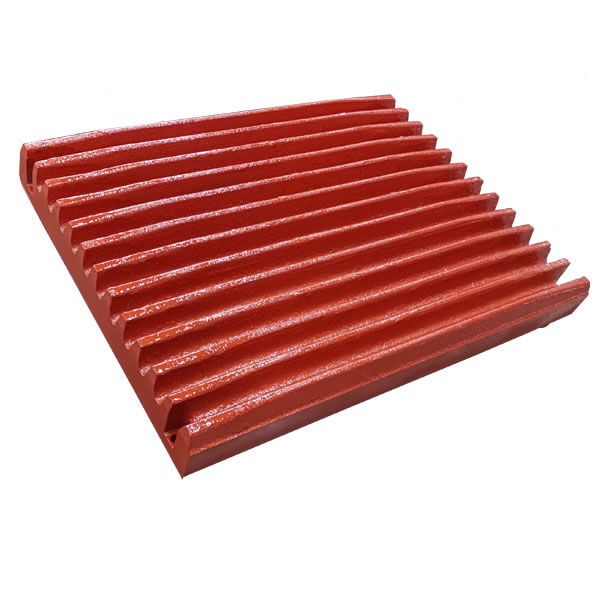

Jaw Plate (Tooth Plate): The core wear-resistant component that comes into direct contact with the ore, typically made of high-manganese steel. It is divided into fixed and movable jaw plates.

Side Guards: Installed on the inner walls of the frame on both sides to protect the frame from wear.

Toggle Plate (Thrust Plate): Serves as both a transmission element and an overload protector. When uncrushable material enters, the toggle plate breaks first, protecting other core components.

Eccentric Shaft/Main Shaft: A core transmission component requiring extremely high strength and toughness.

Bearings: Large spherical roller bearings are typically used to withstand significant impact loads.

Spring Tie Rod: Ensures close contact between the movable jaw and the toggle plate.

2. Cone Crusher

Working Principle: The movable jaw oscillates within the fixed cone cavity, continuously squeezing, bending, and shearing the ore to achieve crushing.

Core Components:

Mantle (Fixed Cone Liner): A liner fixed to the outside.

Concave (Mooring Cone Liner): A liner mounted on the movable cone. Together, they form the crushing chamber and are the primary wear-resistant component, made of high-manganese steel or alloy steel.

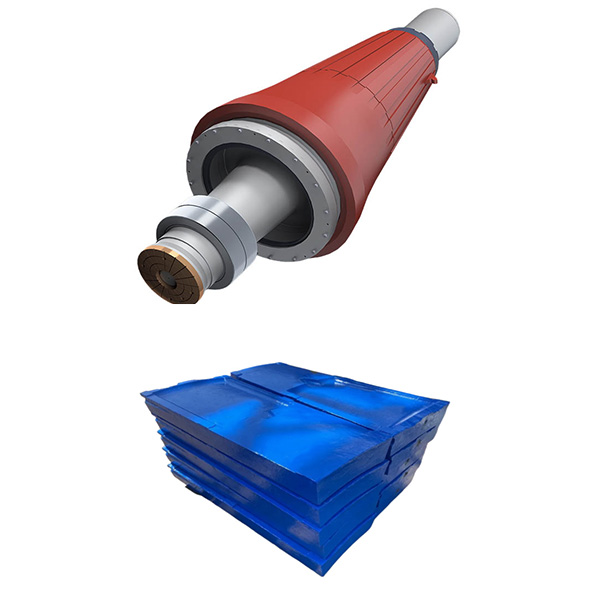

Main Shaft: A core load-bearing and transmission component.

Bowl Bushings/Copper Bushings: These include the main shaft copper bushing and the eccentric bushing. They function as sliding bearings, ensuring smooth operation and require excellent wear resistance.

Hydraulic system components: Used to adjust the discharge opening and release the iron, including hydraulic cylinders, accumulators, and hydraulic pump stations.

Distribution plate and feed hopper: Ensure uniform material delivery to the crushing chamber.

3. Impact crusher (such as a vertical shaft impact crusher)

Working principle: The material is accelerated and thrown by a high-speed rotating impeller, where it collides with the impact plate or the material itself, resulting in crushing ("rock on rock" or "rock on iron").

Core accessories:

Thrower head/impeller lining: Attached to the impeller, it directly propels the material. This wears very quickly and requires high-hardness materials such as tungsten carbide.

Impact block/wear-resistant block: Attached to the periphery of the eddy current crushing chamber to withstand the impact of high-speed material.

Flow channel plate/circumferential guard plate: Protects the upper and lower flow channels of the impeller.

Impeller: The core rotor component, typically a one-piece casting.

Main shaft assembly: Consists of the main shaft, bearing housing, and bearings, requiring high precision and excellent balance.

II. Grinding Equipment and Accessories

Grinding equipment (mills) is primarily responsible for fine and ultra-fine crushing of crushed products until the particle size required for mineral processing is achieved.

1. Ball Mill/Rod Mill

Working Principle: As the cylinder rotates, the grinding media (steel balls or rods) inside are lifted to a certain height and then dropped, impacting and grinding the material.

Core Accessories:

Liners:

Cylinder linings: Protect the cylinder and elevate the grinding media. They come in a variety of types, including corrugated, stepped, and grooved liners, and are made of materials such as high-manganese steel, chromium-molybdenum alloy steel, and rubber.

End Cover Liners: Protect the mill end covers.

Grinding Media:

Steel Balls: Steel balls of varying diameters are added in a graded manner and serve as the primary grinding media.

Steel Rods: Used in rod mills, they provide selective grinding and produce a uniform product particle size.

Feeders/Chutes: Feed the material into the mill.

Discharge devices, such as grate plates and overflow weirs, control the discharge of material.

Gears (speed reducers) transmit power to drive the cylinder. They are key transmission components.

Main bearings support the enormous weight of the entire mill cylinder and are typically sliding bearings or large spherical roller bearings.

2. Semi-autogenous mill

Working principle: This is a type of ball mill, but in addition to steel balls, the grinding media also includes large ore chunks (typically up to 200-300mm), providing both crushing and grinding functions.

Core components: Similar to ball mills, due to the greater impact, the strength and wear resistance of the liner (especially the lifting bars) are higher. The grate design is also more critical to prevent clogging by large chunks of material.

3. Raymond mill/vertical mill

Working principle: The material is crushed by the rotating grinding rollers within the grinding ring.

Core components:

Grinding roller assembly: Consists of the grinding rollers, roller shaft, bearings, etc. The grinding roller is the primary wear-resistant component.

Grinding ring: A fixed, ring-shaped wear-resistant component that works in conjunction with the grinding roller.

Scraper: Scoops up material and throws it between the grinding roller and grinding ring.

Center shaft/main shaft.

Classifier blade: A built-in dynamic classifier used to separate qualified fine powder.

III. General Auxiliary Equipment Accessories

Feeding equipment: Such as the liners and vibrating motors of vibrating feeders.

Screening equipment: Such as the screens, screen plates, vibrator bearings, and springs of vibrating screens.

Conveying equipment: Such as the conveyor belts, idlers, and rollers of belt conveyors.

IV. Accessory Materials and Trends

Common materials: High-manganese steel, high-chromium cast iron, alloy steel, tungsten carbide, ceramic composites, and rubber. The choice depends on impact force, abrasiveness, and cost-effectiveness.

Development Trends:

Wear-resistant material upgrades: Developing new materials with higher wear and impact resistance, such as nanocomposites and functionally gradient materials.

Structural Design Optimization: Computer simulation (such as discrete element method (DEM)) is used to optimize the shape of components such as liners and jaws, improving service life and crushing efficiency.

Intelligent Monitoring: Sensors are installed on key components (such as spindle bearings and mill liners) to monitor temperature, vibration, thickness, and other data in real time, enabling predictive maintenance and avoiding unplanned downtime.

In short, the supply of components for grinding and crushing equipment in metal mines is a technology-intensive field, and their performance is directly related to the operating efficiency, cost, and safety of the entire mineral processing line. Selecting the right components and conducting scientific maintenance are crucial aspects of mine operations management.