Detailed Explanation of Ball Mill Parts Names, Functions, and Our Expertise

At the heart of the grinding industry, the stable and efficient operation of ball mills is critical to production profitability. The key to keeping this "heart" beating strongly lies in the exceptional quality and seamless coordination of each core component. As your professional ball mill parts partner, we not only supply products but also share knowledge, working with you to safeguard every minute of production.

I. Cylinder Section: Armored Guardians, Key to Efficiency

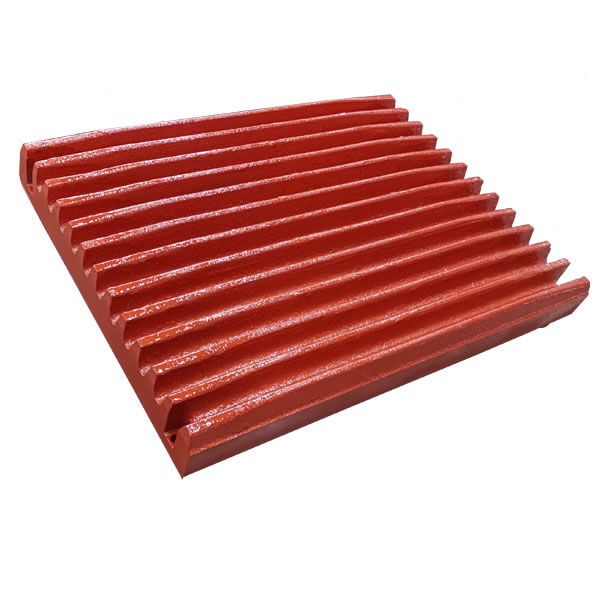

The cylinder is the body of the ball mill, and the ball mill liner inside serves as its true "armored guardian."

Function: It not only protects the cylinder from wear caused by grinding media and materials but also plays a critical role in determining grinding efficiency. Its design (e.g., wave, step, double-wave) directly affects the lifting height and trajectory of the steel balls, ultimately influencing grinding results and energy consumption.

Our Focus: We offer liners in various materials (high manganese steel, high-chromium iron, alloy steel, rubber) and models. Based on your material characteristics and operating conditions, we recommend the optimal liner type and material combination to maximize mill efficiency and reduce overall costs.

II. Transmission Section: Power Lifeline, Precision Gears

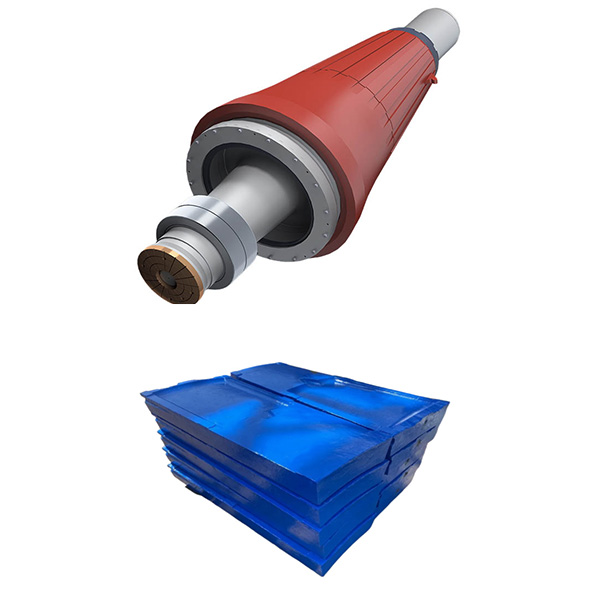

The transmission system is the power lifeline of the ball mill, with its core lying in the precise meshing of the girth gear and the pinion gear.

Function: They transfer motor power smoothly and efficiently to the massive cylinder. The machining precision, heat treatment, and installation of these gears directly impact transmission stability, noise levels, and energy consumption.

Our Focus: We ensure every gear set exhibits high tooth surface hardness, core toughness, and meshing accuracy.

III. Main Bearing Section: Weight-Bearing Shoulders, Foundation of Rotation

The main bearings support the entire weight of the mill, serving as the foundation for its smooth rotation.

Function: Modern ball mills widely use full rolling bearings (trunnion bearings), which offer advantages such as low friction, significant energy savings, and ease of maintenance over traditional sliding bearings.

IV. Feeding and Discharging Section: Material Throat, Gate of Efficiency

Feed/Discharge End Liners: Protect the end covers from wear.

Grate Plates: Act as the "screening officers" of the mill, controlling discharge fineness. The design and wear resistance of the grate holes are crucial.

Lifter Bars: Efficiently discharge qualified materials.

Our Focus: We provide a full range of wear-resistant components from the feed end to the discharge end. Our grate plates feature computer-optimized hole layouts for smooth ventilation and efficient discharge, while our scientifically designed lifter bars significantly enhance discharge speed and prevent over-grinding.

V. Grinding Media: Direct Tools, Core of Cost

Grinding balls and grinding cylpebs are the direct tools for crushing and grinding materials.

Function: Their quality directly affects grinding efficiency, product fineness, and liner wear.

Our Focus: We supply grinding media in various materials (low-chromium, medium-chromium, high-chromium) and specifications. Our high-chromium balls are manufactured using scientific heat treatment processes, ensuring high hardness, excellent wear resistance, and extremely low breakage rates. They effectively reduce cost per ton, making them true tools for enhancing efficiency and cutting costs.

Conclusion: Your Comprehensive Parts Solution Provider

Every component is integral to the life of the ball mill, and every replacement is an upgrade to production capacity. By choosing us, you gain not only high-quality ball mill parts (liners, gears, bearings, grinding balls, grate plates, etc.) but also a complete set of technical solutions and lifelong service commitments backed by deep expertise.

Let us use professional parts to protect your core equipment and build a stable, efficient, and profitable future together!

Zhili New Materials – Your Trusted Ball Mill Parts Partner